Description

GRADES

307Si, 308L, 308LSi, 309, 309L, 309LSi, 309LMo, 310, 312, 316L, 316LSi, 317L, 318Si, 321, 347, 347Si, 409, 409Cb, 409Ti, 410, 410NiMo, 420, 430, 430LNb, 904L, 2209, 2597, 630, NiCr-3 & NiCrMo-3

*Also offered in equivalent DIN Standard

DIAMETER

| MM | 0.60 | 0.80 | 0.90 | 1.00 | 1.20 | 1.60 |

|---|---|---|---|---|---|---|

| INCH | 0.025 | 0.030 | 0.035 | 0.040 | 0.045 | 0.062 |

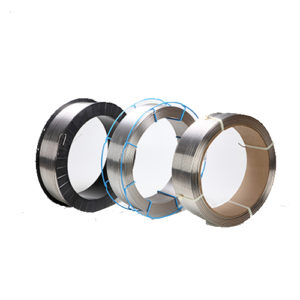

SURFACE FINISH

Bright, Matte & Semi Bright

| SIZE | STANDARD SPOOLS | ||||

|---|---|---|---|---|---|

| NM | INCH | SD 300/BS300 | SD 200/BS200 | SD 100 | |

| 0.60 | 0.025 | 10 Kg. – 20 lbs. | |||

| 0.80 | 0.030 | 12.5 Kg./25 lbs. 15 Kg./30 lbs. – 33 lbs. |

5 Kg./10 lbs. | 1 Kg./2 lbs. | |

| 0.90 | 0.035 | ||||

| 1.00 | 0.040 | ||||

| 1.20 | 0.045 | ||||

| 1.60 | 0.062 | ||||

PAIL PACKING SYSTEM FOR AUTOMATIC WELDING

MIG Wires in Fiber Drums of 100-125 kg (200-250 lbs)/200-225 kgs (450 – 500 lbs) available for high productivity GMAW process and robotic applications.

- Increase in productivity : With less down time compared to standard spools.

- Less wear on welding machine parts : No twist pay-off system.

- Clean conditions : No contamination from the shop environment.

- Low space requirement : The drum diameter is only 510 mm.

- Short setup time : Adapt quickly and easily to any conventional feeder.

We also offer ‘Customized Packaging & Labelling Solutions’ as per requirement.