Description

- Resin pour insulation system with VPI using solvent-less epoxy resin.

- Die penetration and ultrasonically tested rotor shafts.

- Two stage dynamic balancing of rotors complying with Grade 2.5 of ISO: 1940.

- Copper/copper alloy bars tight fitted in slots and brazed to short circuiting ring.

- Grease lubricated ball /roller bearings.

- Oil lubricated sleeve bearings to withstand high speed and heavy load

Scope

| OUTPUT POWER | VOLTAGES | FRAME SIZE | STANDARD |

| Up to 2000 kW | Up to 6600 V | 355 to 710 | IEC, IS |

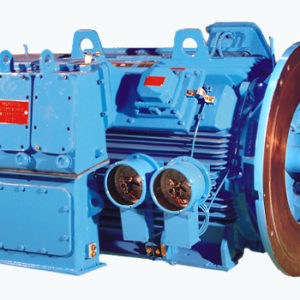

Construction

Stator frame has a barrel type construction made from thick fabricated steel to withstand internal pressure. Stringent checks like pressure tests are in place to ensure to high degree of welding quality. Adequate care is taken during machining to ensure a perfect concentricity of stator bore leading to minimum vibration level and optimum heat transfer. For higher frame sizes i.e. 630 and 710 the frame is of TETV construction. The tubes are double expanded in thick end plates to provide protection against leakage in case of explosion.

Technical Specifications

Degree of Protection : IP55

Enclosure : IC 411 / IC 511

Dimensions : As per IEC: 60072-A

Output : Up to 2000kW

Supply Voltage : 415, 690, 3300, 6600

Supply frequency : 50, 60 Hz

Mounting : IMB3, IMV1, IMB35

Frame Size : E355, E450, E560, E630*, E710*