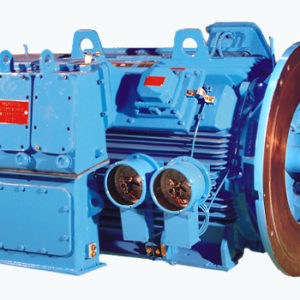

Description

Offered From : Europe

- Reduced initial capital expenditure and lower operating costs.

- Light weight with high power to weight ratio.

- Reinforced insulation superior to Class F with Class H VPI, temperature rise limited to Class F ensuring high insulation strength & protection from environment.

- Non sparking material for fans. Caulking of rotor bars for tight fit in rotor slots.

- Pre-start purging facility for removal of hazardous gases from the enclosure before starting (Purging instrumentation is optional).

- Minimised vibrations, noise and longer bearing life through minimised unbalance at every stage and precision balancing of Rotors using state of art dynamic balancing machine to grade better than 1.0.

- Maintaining adequate clearance between stationery and rotating parts.

- Providing adequate clearances and creep age paths between live phases and between phase and earth in the terminal boxes.

- Providing positive locking features for terminating the cables to guard against loosening of the termination due to vibrations etc

Offered From : India

- Reduced initial capital expenditure and lower operating costs.

- Light weight with high power to weight ratio.

- Reinforced insulation superior to Class F with Class H VPI, temperature rise limited to Class F ensuring high insulation strength & protection from environment.

- Non sparking material for fans. Caulking of rotor bars for tight fit in rotor slots.

- Pre-start purging facility for removal of hazardous gases from the enclosure before starting (Purging instrumentation is optional).

- Minimised vibrations, noise and longer bearing life through minimised unbalance at every stage and precision balancing of Rotors using state of art dynamic balancing machine to grade better than 1.0.

- Maintaining adequate clearance between stationery and rotating parts.

- Providing adequate clearances and creep age paths between live phases and between phase and earth in the terminal boxes.

- Providing positive locking features for terminating the cables to guard against loosening of the termination due to vibrations etc

Country-Wise Scope

| OUTPUT POWER | VOLTAGES | FRAME SIZE | \STANDARD | |

| India | 180 kW to 12000 kW | Up to 11000 V | 355 to 710 | IEC, IS |

| Europe | 180 kW to 12000 kW | Up to 11000 V | 355 to 710 | IEC |

Technical Specifications

Frame range : 355 to 710

Rating : 180 kW to 12000 kW

Insulation : Class ‘F’ and ‘H’

Degree of protection : IP55

Type of cooling : IC0A6, IC1A7, IC3A7, IC6A6A6, IC6A7W7

Standards : IS/IEC 60079-15:2004